Rutgers NJAMI Team Create Lightweight Replica of Rutgers Presidential Medallion

In advance of the November 7 inauguration of William F. Tate IV as the 22nd president of Rutgers University, the School of Engineering (SOE) teaming with the Makerspace was asked to make a lightweight replica of the presidential regalia’s medallion and chain. Under the direction of SOE’s Henry Rutgers Distinguished Professor and Director of the New Jersey Advanced Manufacturing Institute (NJAMI) Yuebin Guo, a team proficient in design, materials, 3D printing, and computer numerical control (CNC) milling collaborated on a plan to successfully complete the task.

Commissioned by past chairs of the Rutgers University Boards of Governors and Trustees, the Rutgers presidential medallion and chain was first presented at the inauguration of Francis L. Lawrence in 1990.

The medallion itself displays the university seal with an outline of the state of New Jersey inset with garnets marking Rutgers’ presence in New Brunswick, Newark, and Camden. Designed and cast in sterling silver by Mason Gross School of the Arts Professor Robert Cooke and alumnus Don Myhre, the chain represents the chain of office.

Both chain and medallion are decorated with ivy that represents the university and oak leaves, representing the red oak, the state tree of New Jersey.

A Collaborative Effort

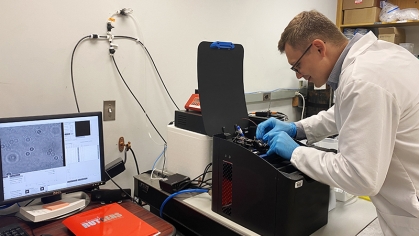

Guo’s team of NJAMI doctoral students and staff, together with the Makerspace director Stephen Carter and his student

staff, were undaunted by the challenge.

To address the lack of existing files, the team created computer-aided design (CAD) files from their own measurements, capturing the intricate details beautifully rendered in the original.

Next, using their new CAD files, they produced a 3D-printed plastic medallion and chain with metallic finished coating.

A second replica of the medallion and chain was based on the CAD files that were then milled using a numerical control (CNC) machine at NJAMI in Richard Weeks Hall of Engineering. The finished machined aluminum replica reduced the weight of the original medallion and chain by 70%.

Guo is pleased to report that the hundreds of hours of teamwork that contributed to the success of both projects and processes added up to “a unique and invaluable learning experience for the team. Students appreciated the opportunity to practice and master additive and subtractive manufacturing skills in a short period of time.”