Ryan Sills Receives NSF CAREER Grant

Five-year award supports development of a quantitative understanding of how, why, and where cracks grow in metals.

Ryan Sills, an assistant professor in the Department of Materials Science and Engineering (MSE) has been awarded a $622,248 National Science Foundation (NSF) CAREER award to reconcile theoretical inconsistencies to better understand and predict fracture of metals.

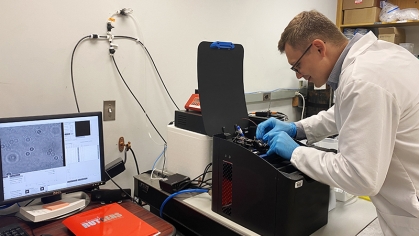

The highly competitive and prestigious NSF CAREER grant funds research and educational initiatives of faculty at the beginning of their careers. Sills leads the SoE Micromechanics of Deformation (mMOD) Research Group, which focuses on applying advanced computational tools to study the mechanical behaviors of materials. Before joining the MSE faculty, he was a staff member at Sandia National Laboratories in Livermore, CA.

“With this award, Ryan is able to expand his integration of concepts across size scales from nanometers to centimeters,” says MSE distinguished professor and department chair Lisa Klein. “He is using physics-informed machine learning to understand how materials perform in common situations.”

For Sills, the NSF CAREER award validates his decision to go into academia after nine years at Sandia. “The question for me was can I hack it, write proposals soliciting funds, and do research on my own,” he explains. “This award confirms that I made the right choice. It’s a tremendous opportunity to get some good work done – and focus on something that will make an impact.”

Resolving Theoretical Inconsistencies

Fractures resulting from the growth of cracks in metals pose a pervasive – and costly – problem for everything from aircraft and automobiles to buildings and power plants.

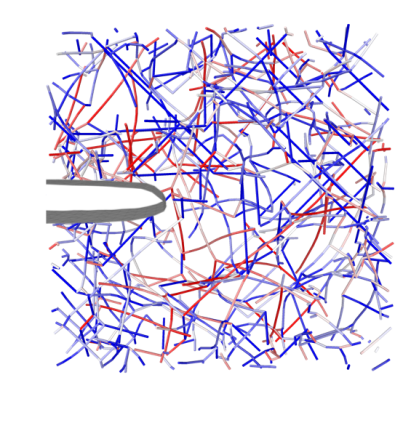

According to Sills, there are currently two schools of thought in considering metal fractures – and both are at odds with each other. While one focuses on the crack tip, the other concentrates on a region surrounding the crack tip called the plastic zone. Sills proposes to reconcile this fundamental inconsistency, which leads to inaccurate predictions of fracture, by developing a new theory of fracture in metals that “doesn’t put its head in the sand.”

He explains that “the crack tip and the plastic zone exist simultaneously. You need to think about both at the same time. The project goal is to reconcile this inconsistency with models to predict when embrittlement – when the material becomes susceptible to fracture – and metal fractures might occur.”

Such a holistic and quantitative understanding of how, where, and why cracks grow in metals, could ultimately lead to the development of better material models for the design of cost-efficient, fracture-resistant materials and structures for energy, defense, aerospace, and transportation.

A Provisional Machine Learning Patent

Sills will be using physics-based machine learning to create a fracture model that simultaneously captures the interplays between the crack tip and plastic zone that impact fracture behaviors such as dislocation multiplication (dislocations are defects present in all metals) and the growth of cracks during cyclical loading.

“One of the challenges of my approach is that it is very expensive to model computationally,” Sills notes. To address this challenge, he has developed machine learning methods that will reduce computational costs and be applicable to a range of science and engineering applications. Based on the potential of these methods, he has filed a provisional patent with the Rutgers Office of Research Commercialization.

A National Lesson Plan for High Schools

NSF CAREER grants include a significant outreach component. Sills, who plans to hire a post-doc for the first year of the project, expects that graduate and undergraduate students will also contribute to the research effort.

In addition, over the course of the project, Sills will be working with the National Science Teaching Association (NSTA) and local high school science teachers to develop a user-friendly lesson plan for high school science students to perform and analyze simulations of metal fracture.

“I’m proud of the collaboration I came up with,” Sills reports. “We’ll pilot with local teachers before releasing the lesson plan nationwide at the end of the project.”